Track rod ends are a small yet essential part of your vehicle’s steering system.

In fact, without track rod ends, you would struggle to steer your vehicle at all.

Read on and find out what a track rod end is, what it does, and when you need to replace it.

Page Contents

- What Are Track Rod Ends?

- What Do They Do?

- Are They the Same as Tie Rod Ends?

- How Long Do Track Rods Last?

- What Are Bad Track Rod Ends Symptoms?

- How Do You Change a Track Rod End?

- What Happens During a Track Rod End Replacement?

- How Much Does a Track Rod End Replacement Cost?

- Should You Replace Track Rod Ends in Pairs?

- Can You Drive on a Damaged Rod?

- How Often Should Track Rod Ends Be Replaced?

- FAQs

What Are Track Rod Ends?

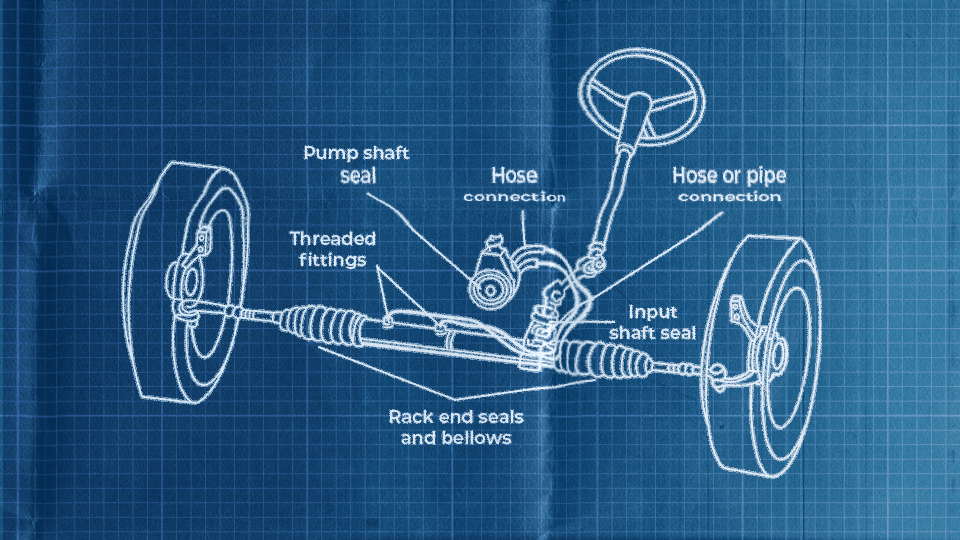

Track rod ends are small and flexible ball joints in your car’s steering system.

They sit on the end of track rods and connect them to the steering rack.

A track rod end is made of two rods – an inner and an outer one – which steer the car.

The outer rod is attached to the steering knuckle, and the inner rod connects to the steering rack and pinion.

Some are sealed, whilst others require greasing every 6,000 miles.

What Do They Do?

Track rod ends swivel and allow the steering rack to move the wheel, by transmitting force from the rack gear to the front wheel steering knuckle.

Steering systems depend on there being a fully functioning track rod which connects it to the wheels.

Your car won’t turn without track rod ends – they are one of the major pivots in the steering system.

For your car to move in the right direction, the track rods and steering system must be fully aligned.

In a rack and pinion system, these track rod end ball joints rotate and allow everything to move effectively.

The track rod is fixed and the wheels swivel thanks to the track rod ends.

Without flexible track rod ball joints and power steering, you will struggle to turn your car at all.

Are They the Same as Tie Rod Ends?

Yes, track rod ends are the same as tie rod ends – just as tie rod and track rod are the same thing.

American English typically uses ‘tie rod’ and ‘tie rod end’, whilst British English uses ‘track rod’ and ‘track rod end’.

How Long Do Track Rods Last?

There is no set time frame for track rod end replacement, but their lifespan can be affected by your driving style.

The smoother you drive, the better the chance of giving your track rod ends a long lifespan.

The outer track rod end is protected by a rubber boot to keep grease in and dirt out, but it can crack over time.

This will allow moisture to get in, causing corrosion and possibly even premature tyre wear.

Likewise, the ball joint is full of grease so it moves easily, but when a dust cover is damaged, this allows grease to seep out and dust to get in.

What Are Bad Track Rod Ends Symptoms?

Your track rod ends may be bad if you notice any of the following symptoms:

- Steering wheel feels loose

- Vibrations in the steering wheel

- Unresponsive steering

- Imprecise steering

- Knocking or clunking noises (when driving)

- Premature or uneven tyre wear

As your track rods wear, they can become loose and may rattle at the joints.

Dirt can also get into the joint if the rubber boot cracks, meaning you will likely hear a grinding noise as you steer.

Bad track rods or track rod ends can cause car suspension problems – and the issues for both are similar – so your suspension could be at fault, instead.

How Do You Change a Track Rod End?

Changing a track rod end is not always an easy job.

First, you must identify which steering system your car uses – some are easier to replace than others.

Most ball joints are screwed onto the end of track rods – so replacing them is fairly straightforward - but some vehicles have one-piece track rods with integrated ball joints.

This is the case in certain Audi, Volkswagen and Renault vehicles – which have one piece track rods with integral ball joints.

In these cases, the whole track rod must be replaced.

If you decide to replace a track rod end in a rack and pinion steering system yourself, remember to turn the steering wheel very slowly whilst the front wheels are raised.

Hydraulic pressure can build up in the steering rack housing if you don’t.

You could inadvertently cause one or both rubber gaiters protecting the track rod ball joints to burst, leading to an increase in repair costs.

To make sure the job is done right, we recommend that you book an appointment at a local garage to have this job carried out for you.

How to Change a Track Rod End in a Special Rack and Pinion System

To change a track rod end, you will need to work under the car.

Jack up the front and support it on axle stands.

Make sure that the handbrake is firmly on, and put chocks behind the rear wheels.

You can then remove the front wheels.

When you remove and replace the track rod ball joints, make sure that they go on in the same position.

This determines the front wheel tracking for your vehicle, which is incredibly important for balance and tyre wear.

You can then replace the wheels.

Make sure that you book a wheel alignment appointment soon, as any error in fitting the track rod ends can cause rapid tyre wear and affect your handling.

How to Change a Track Rod End in a Special Rack and Pinion System

Some vehicles have special rack and pinion systems.

On one side, the track rod is adjustable and you can replace the ball joint as outlined above.

On the other side, the track rod end is integrated – meaning the entire rod must be replaced.

Certain vehicles have more complex track rod ends, which need to be removed along with the whole rack gaiter.

In these cases, you should only attempt a track rod end replacement if you are an experienced mechanic.

What Happens During a Track Rod End Replacement?

During a track rod end replacement, a mechanic will raise the front of your vehicle and remove the road wheel.

The mechanic can then check the tie rod for movement and remove the faulty track rod end.

In some cases, the track rod end may be seized in position if it has been frequently covered in water and road debris.

This means that the mechanic may need to use heat to undo the retaining nuts, and a ball joint splitter to get the part out of the steering knuckle.

A new track rod end can then be fitted, and the mechanic can tighten up the components before refitting the road wheel and lowering the car.

How Much Does a Track Rod End Replacement Cost?

Per side, a track rod end replacement can cost between £70 and £160 - with labour costs being higher than the price of the part itself. Once the suspension components are replaced, tracking can cost anywhere from £40 to £70.*

It is often the case that if one track rod end is worn, then they are all wearing out.

Replacing both can promote even wear, extend the lifespan of your tyres and help you avoid more costly repairs later down the line.

*Based on data taken from Bumper

Should You Replace Track Rod Ends in Pairs?

You should always replace both track rod ends at the same time to promote even wear, avoid expensive repairs and to extend the lifespan of your tyres.

If one is worn, it is likely that the other one is, too.

Can You Drive on a Damaged Rod?

Whilst you can technically drive on a damaged rod, you will not have control of steering if the part begins to disintegrate.

As you can imagine, this can be dangerous – so don’t drive on a worn track rod.

To check if you need to replace your track rod ends, grab one of your front wheels and push with one hand whilst pulling with the other.

If you notice a great deal of movement, you should book a replacement.

We would also recommend that you book a wheel alignment appointment and a wheel balancing appointment at the same time, as a faulty track rod end can have an affect on both of these.

How Often Should Track Rod Ends Be Replaced?

There is no replacement interval for track rod ends, but you should change them as soon as you notice any wear or damaged seals.

Track rod ends can fail due to damage caused by poor road conditions and debris, so make sure you check their condition regularly.

FAQs

16 replies to "What Are Track Rod Ends? (And What Do They Do?)"

Joy Thomas

August 31st, 2021

Drew Hickman

August 31st, 2021

steve gregory

September 3rd, 2021

Drew Hickman

September 3rd, 2021

Daisy

March 14th, 2022

Drew Hickman

March 16th, 2022

Ruth

August 11th, 2022

Dave

August 26th, 2022

Drew Hickman

August 26th, 2022

Jane

February 5th, 2024

Eve McPherson

February 5th, 2024

Really just facts

September 26th, 2023

Eve McPherson

September 26th, 2023

Mark Fitzpatrick

February 5th, 2025

Eve McPherson

February 5th, 2025

Leave a comment